Create spraying program

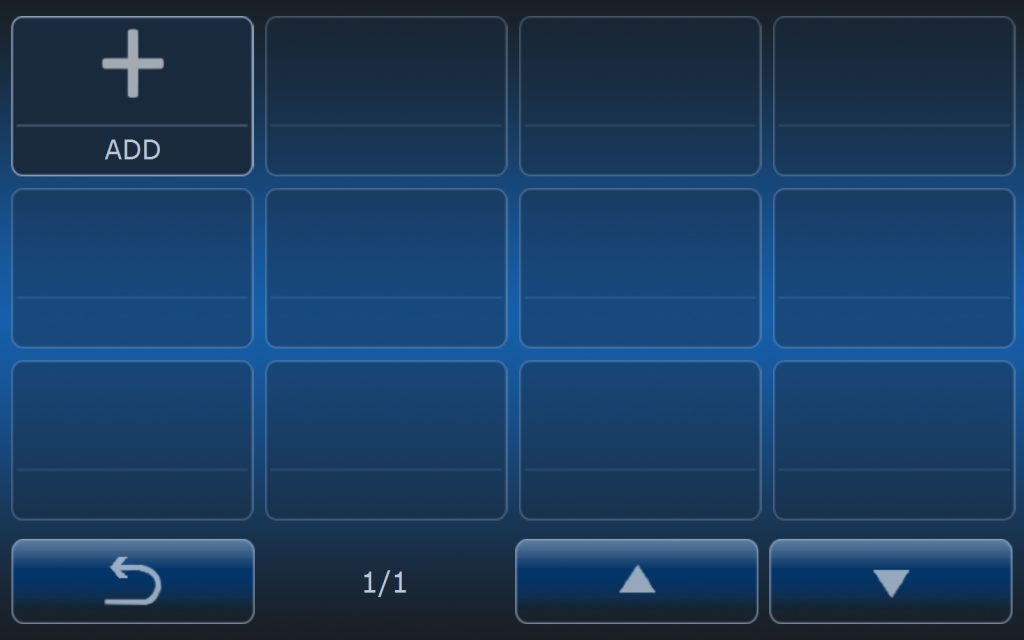

Correct operation of the computer depends on creating the correct spraying programs. To create a new program, press the tile with the current program’s name or – if no program has yet been created – the tile with the text: NEW PROGRAM.

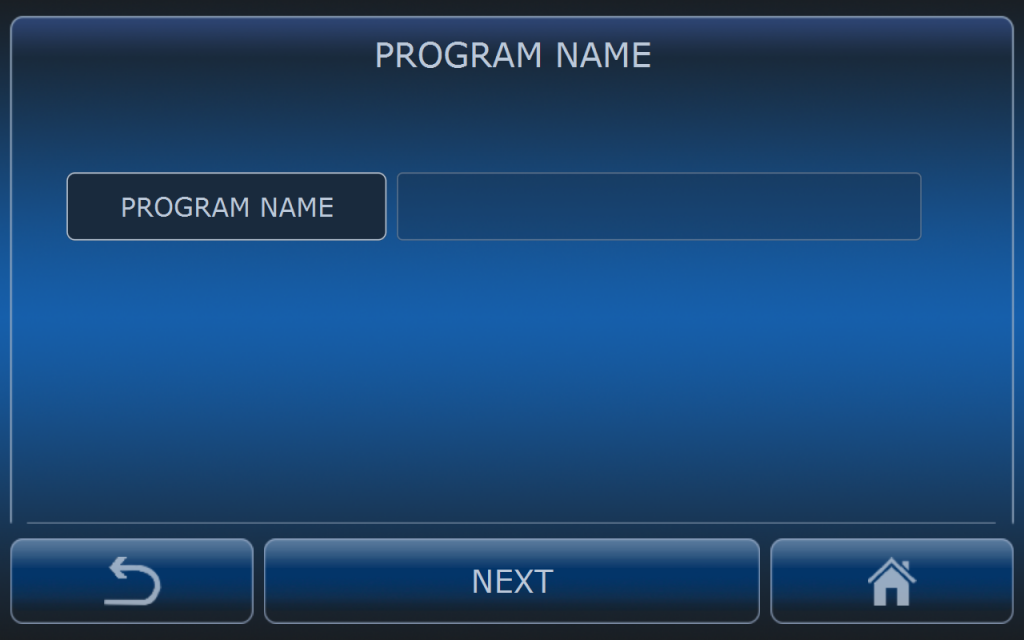

Press the tile to display the menu with the ADD tile. Press the ADD button to create a new program. This will initiate the new program creation process. Enter the name of the program on the first screen using the touch keyboard and confirm it by pressing the ENTER or NEXT button.

After pressing ADD + button first put your individual name of the spraying program. It is good to put short names so they are better visible on the screen.

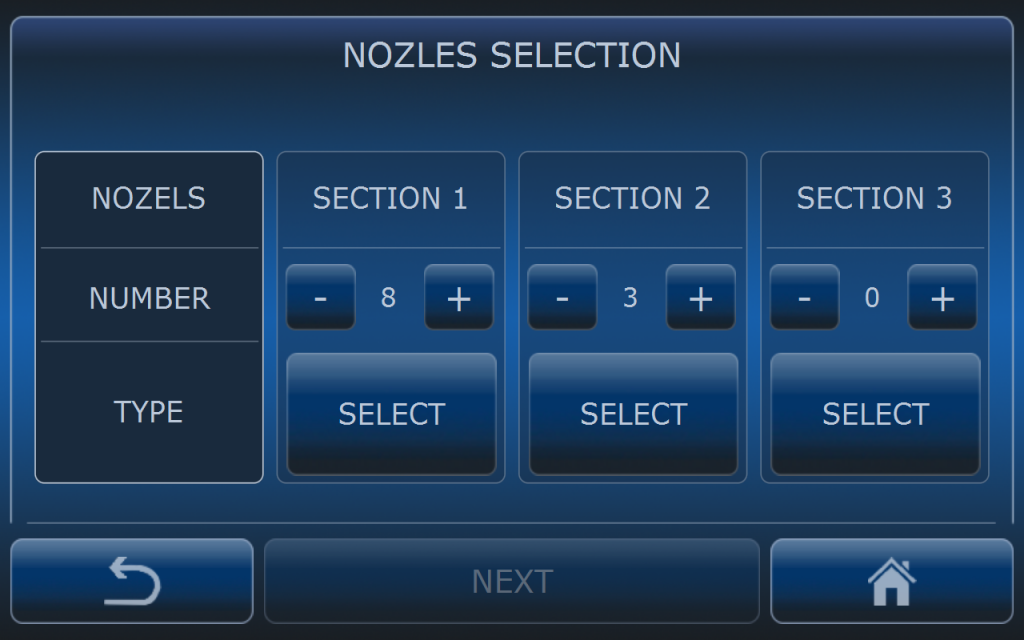

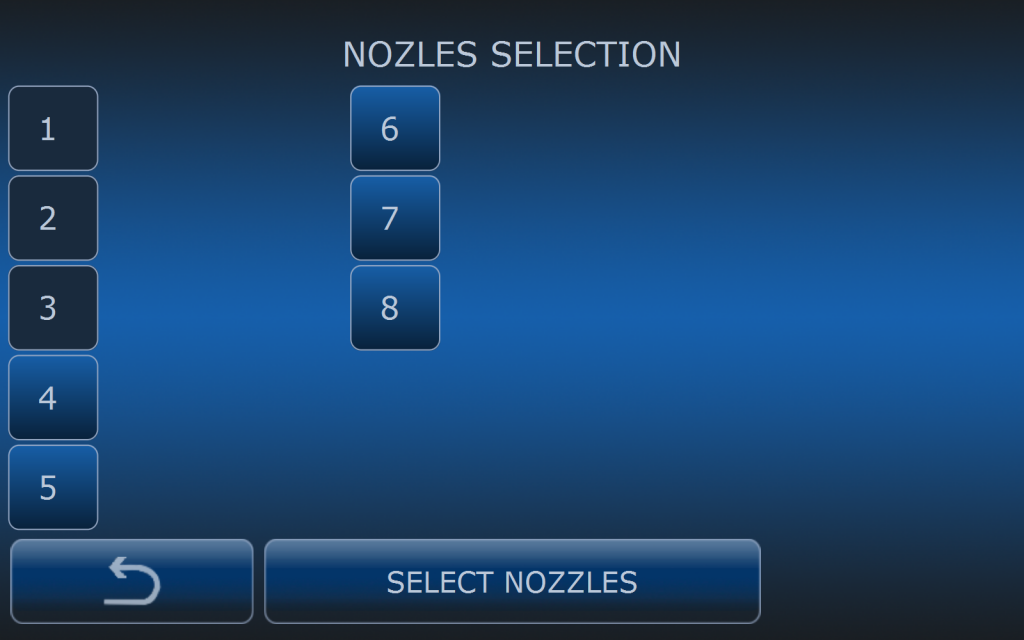

Select number of nozzles in each section. Remember to count nozzles only on one side of the sprayer. Section 1, 2 and 3 represents sections if the tower in the sprayer is divided into vertical sections. Then press SELECT button to set up type of the nozzles.

The default assumption for the program is that sections on both sides are symmetrical and that all nozzles in each sections are homogenous.

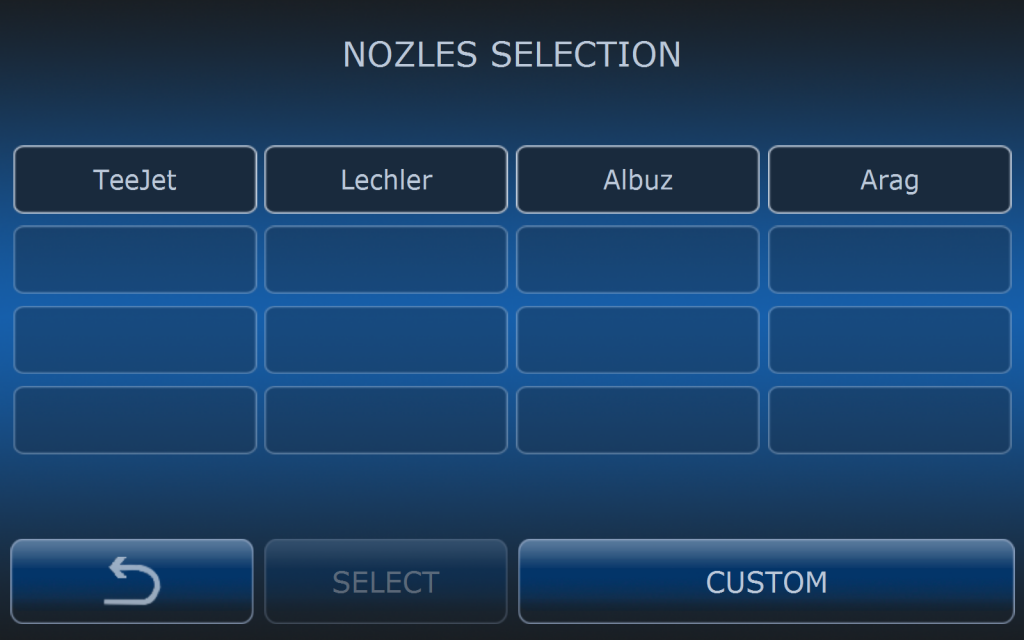

You can choose from different type of the nozzle manufacturers.

Most popular nozzles are already on the list.

Tips and tricks

If the nozzle is not available on the list you can choose another which has similar size.

Alternatively, each nozzle may be defined individually. The computer supports various types of user-installed nozzles within the same section. This setup is frequently used in hop farming. In order to do that, first press the INDIVIDUAL button. Then press the numbers of the individual nozzles in a section and finally assign nozzle models to those numbers. Repeat the steps until all numbers have a nozzle model assigned.

Nozzle numbers in the individual section are counted from the bottom of the fan

attachment. Up to 15 various nozzles can be assigned to a section in the

individual mode. All numbers must have nozzles assigned.

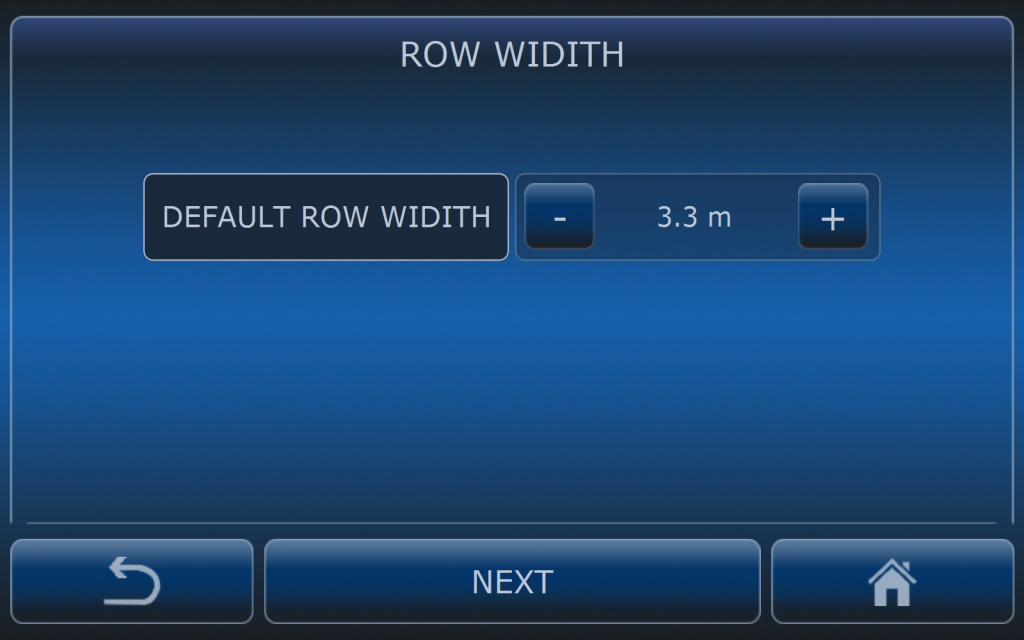

Next step is setting up row widith.

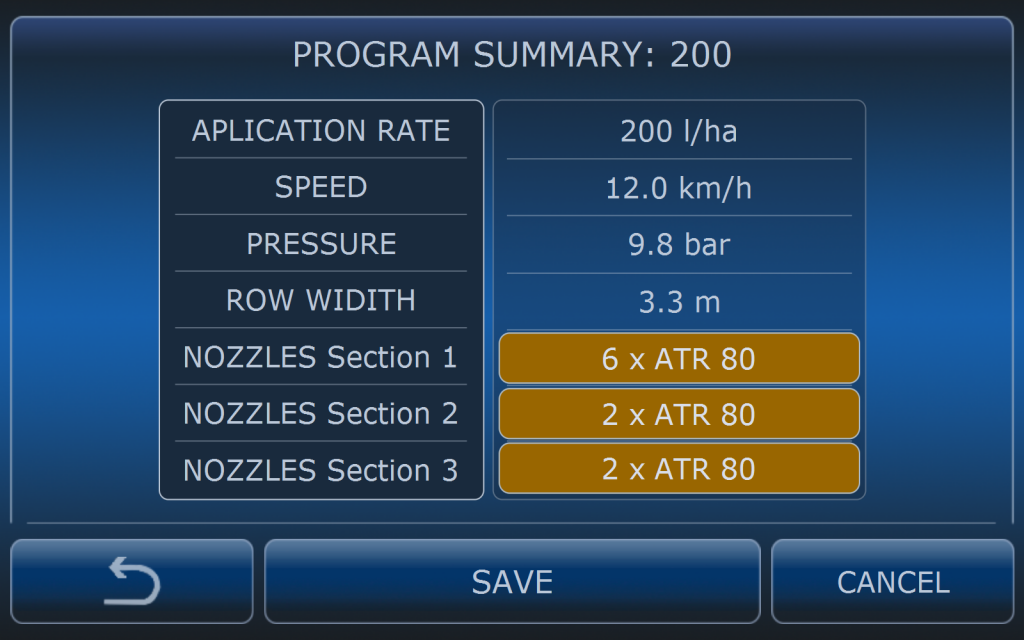

The last step it setting up aplication rate. Choose APPLICATION RATE you want to get and computer will calculate what pressure and speed you need to get this rate with selected nozzles. Speed and pressure settings are only calculator to check if the selected nozzles are suitable to achieve demanded rate. On this picture it is shown that for 200l/ha rate and at 12km/h working pressure will be 9.8 bars. When in AUTO mode computer will try to keep constant application rate which is set in this menu.

Remeber that it will work properly only when application rate is in range of the nozzles.

Last screen is summary screen for quick overview of selected settings.