First start

You can start the device for the first time after ensuring that it is properly connected to the electrical power supply.

First, switch on the computer in the cabin by pressing the button 9 marked in Figure 5.3. Second, switch on the sprayer module by pressing the button 2 marked in Figure 5.15.

Illumination of the power switches will confirm module activation. Electric valve control buttons will also be illuminated. Until complete computer start, the lights will be fading in and out. This button illumination behavior indicates correct device start-up process.

The process of starting-up and initializing communication between the computer and the sprayer module takes some seconds. After this time, modules begin pairing.

The computer and sprayer module have been factory-paired in the delivered device kit. There is no need to additionally set up the device in order to connect the subassemblies correctly.

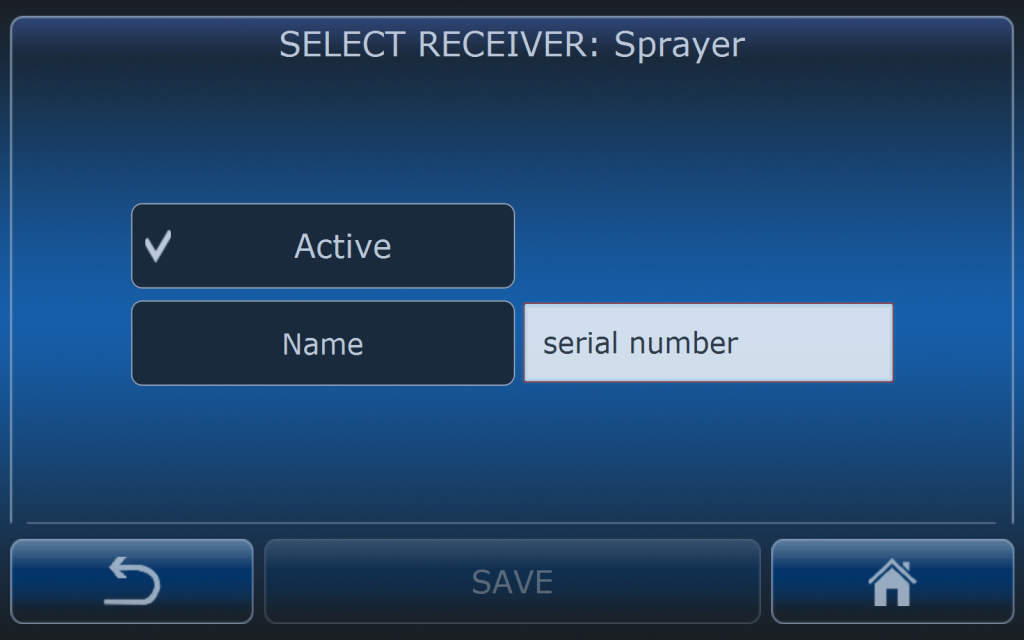

Where necessary to connect a computer with display to another sprayer controller, changing the sprayer controller name is required. First, read the sprayer controller serial number (case sensitive). Then activate both devices. On the computer with the display, go to MENU>IMPLEMENTS>selected implement> RECEIVER.

Put the serial number here.

Some implements do not need receiver so then it must be not active.

If the computer asks for a PIN code, enter the default one (1234) or the code previously changed by the user. Then, in the “name” field, enter the sprayer controller serial number and press SAVE at the bottom of the screen. Once done, restart the computer with the display by pressing the power button.

The device pairing process is usually very quick (some seconds) but sometimes it may take longer. After the devices are properly paired, the CONNECTING TO THE SPRAYER CONTROLLER screen will disappear, or a red STATUS tile will start flashing with the message: WAITING FOR CONTROLLER. Following proper connection of the devices, all tiles with readings should display the current information from the sprayer sensor: speed, pressure, liquid level (optionally).